- Nuclear Fuel Industries,Ltd

- BUSINESS

- Nuclear Fuel

Nuclear Fuel

The Nuclear Fuel Cycle and NFI’s Role

The nuclear fuel cycle is a framework in which uranium that can undergo fission again and plutonium that has been newly generated are recovered as energy resources from the fuel used in nuclear power plants and then re-used as fuel for nuclear power generation. NFI is responsible for a part of the nuclear fuel cycle including the processing of uranium, the raw material, into "fuel assemblies" that can be used in nuclear power plants.

Light Water Reactor Fuel

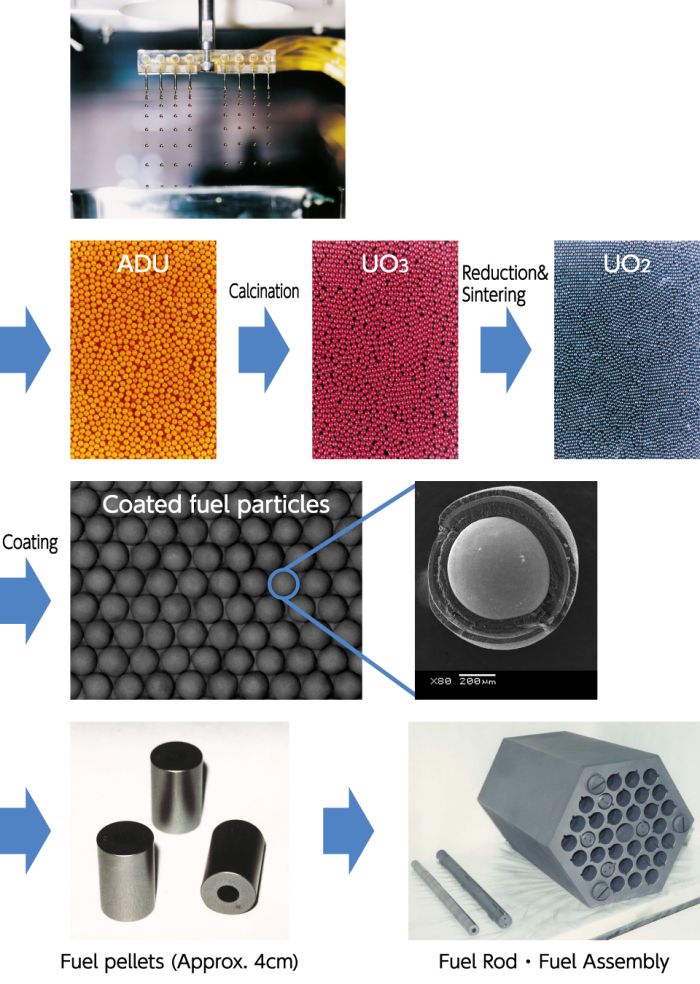

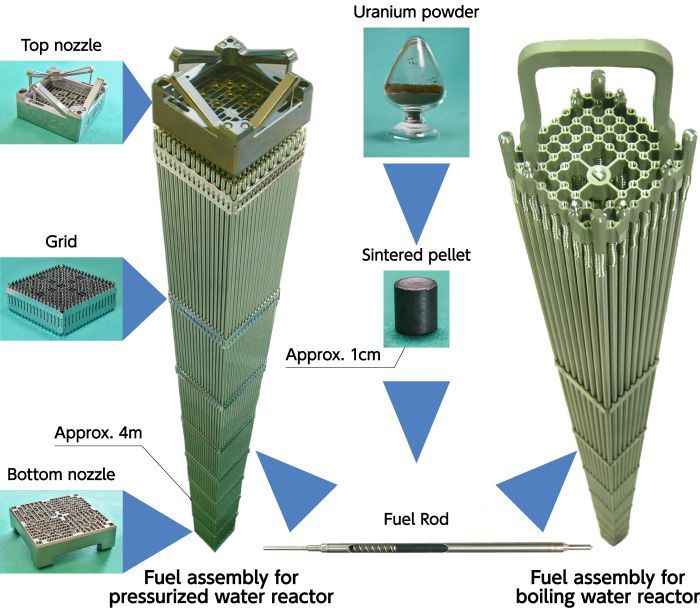

There are two types of commercial nuclear reactors in Japan, boiling water reactors (BWRs) and pressurized water reactors (PWRs). We are the only Japan’s company that can manufacture "fuel assemblies" for both types of reactors. Fuel assemblies are manufactured by pressing and sintering uranium dioxide powder to pellets, inserting them into metal tubes and sealing, and then bundling such tubes together into an assembly. In order to transport the fuel assemblies safely to nuclear power plant, we are also working on the design and development of fuel transport packaging which can protect the fuel from accidents, such as falling from high place and fire.

Fuel-related Technologies Other than Light-water Reactor Fuel

In addition to manufacturing of fuels for commercial reactors, NFI also owns expertise and technologies for manufacturing fuels for the high temperature gas-cooled research reactors. We have manufactured and delivered the fuels for high temperature engineering test reactor (HTTR) to Japan Atomic Energy Agency (JAEA).