- Nuclear Fuel Industries,Ltd

- BUSINESS

- Engineering

Engineering

Fuel Inspection

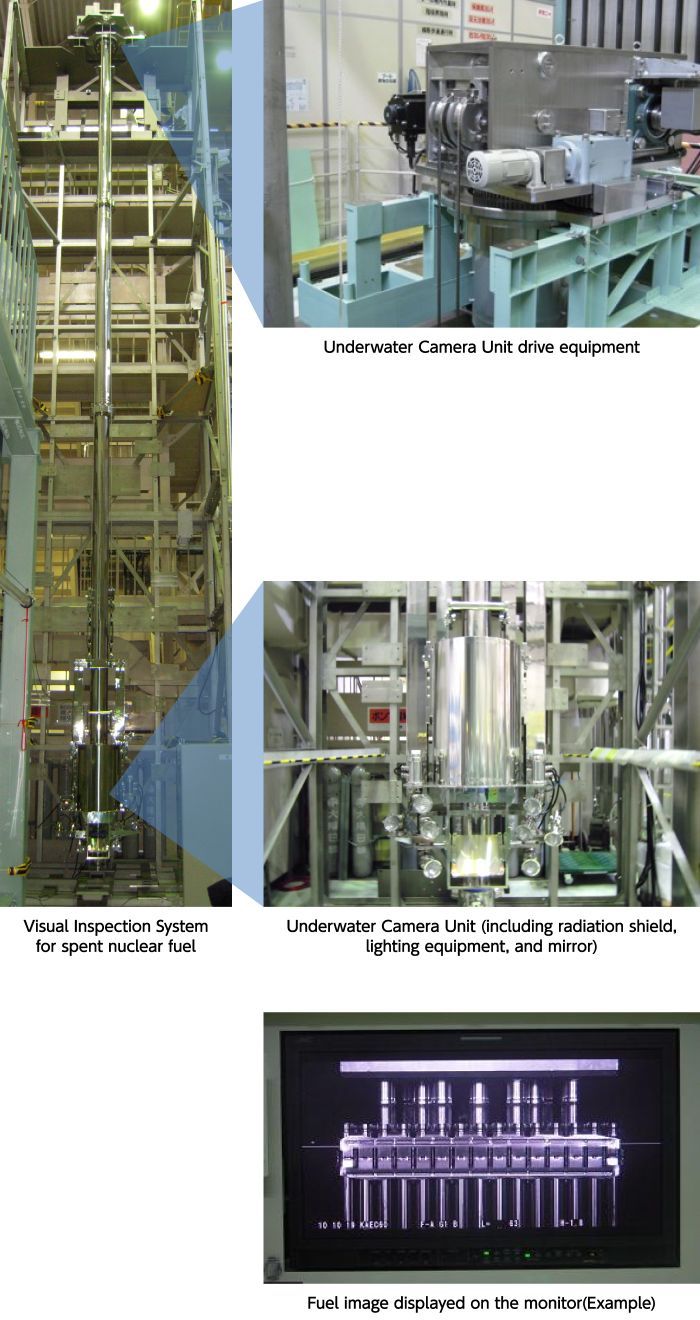

Various sorts of fuel inspections are conducted to verify the fuel integirity on a regular basis while the reactors are shut down. We are contributing to the safe operation of nuclear power plants through the design and manufacture of fuel inspection devices and inspection services using such devices.

Development of Non-Destructive Testing Equipment and Inspection Services

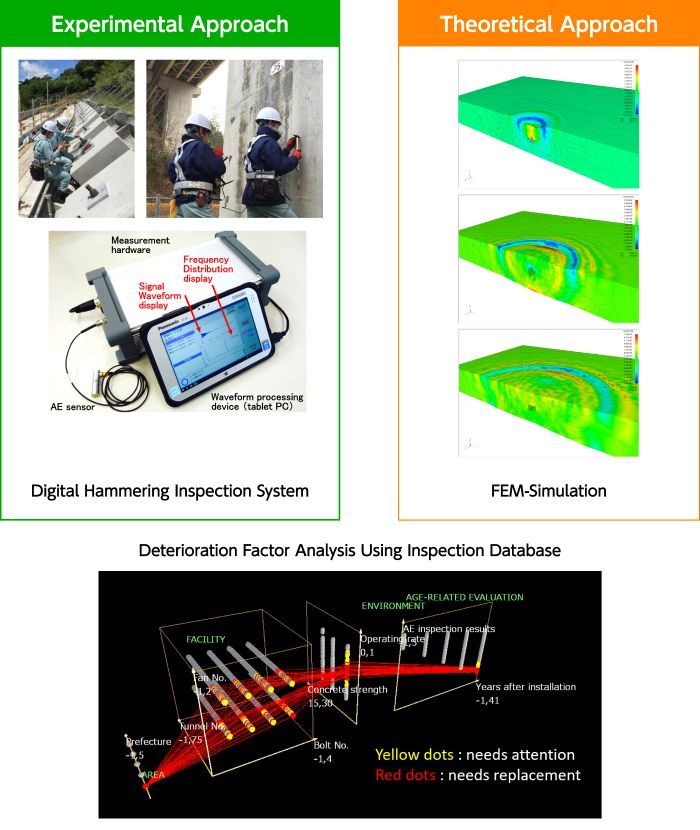

In addition to fuel inspections, we provide non-destructive inspection services for various equipment and components in nuclear reactors, such as steam generators, valves, bolts, and pipes. We are also working on the development of next generation non-destructive inspection as well as hammering inspection using acoustic emission technologies in order to improve the reliability of inspection.

Plant Maintenance Services

A new inspection system for nuclear power plant facilities has been introduced to perform " necessary inspections at necessary times" based on scientific and technical evidences. To ensure optimal maintenance and safe operation of various types of plant facilities, we are offering support for the optimized planning of maintenance, inspection, and repair (i.e., formulation of maintenance programs) for various types of facilities. We are also providing support services for restarting nuclear power plants that have been in a shutdown state for a long period and for ensuring the safety of nuclear power plants that have restarted operations.

Development of Power Plant-Related Engineering Systems

Utilizing our extensive experience with in-core fuel management and plant maintenance services, we are developing and maintaining various systems used in nuclear power plants, such as systems for accounting and weighing of nuclear materials and for water quality management support.

Social Infrastructure Diagnosis Services

For the issue of social infrastructure aging, which is becoming increasingly serious, the Japanese government has made the inspection of roads (including tunnels and bridges) nationwide mandatory, and accordingly there is a growing need for efficient inspection methods. Under such circumstances, we are offering diagnostic technologies for social infrastructures by means of hammaering test utilizing acoustic emission sensors and social system diagnosis technologies equipped with artificial intelligence taking advantage of big data, both of which have been developed based on our non-destructive inspection technologies cultivated through our experience with nuclear power plant services.